Powder concentrator

1.Mineral powder separator

2.Flyash grade separator

High-efficiency calcium powder special classifier

Shandong Kaidong Construction Machinery Co., Ltd. is a high-tech enterprise specializing in the R&D and manufacturing of powder conveying and grading equipment. The KD series ultrafine powder classifiers researched and developed by it have been widely used in many cement factories across the country. And it is in the same industry in terms of large scale. It can produce ultra-large high-efficiency classifier KD series ultra-fine powder classifier with a processing capacity of 100T/H, fly ash and 600T/H, and ultra-fine cement. Introduced in 2000, based on the technology of Onoda O-Sepa powder classifier in Japan, it is a new type of high-efficiency classification equipment successfully developed through digestion and absorption and independent innovation. /m3 dry air, compared with the current turbine classifier, it has the following outstanding advantages:

1. There is a side wall effect in the turbine classifier: the current turbine classifier is only equivalent to adding a rotating turbine device in the middle of the cyclone, and the dusty gas mixed with coal ash enters the cyclone tangentially and then rotates at a high speed. Particles are thrown to the wall and fall under the action of centrifugal force. At the same time, due to the influence of the side wall effect, the fine ash near the cylinder wall is also thrown to the cylinder wall and mixed into the coarse ash under the action of centrifugal force, resulting in unclean separation of fine ash.

2. There is a velocity gradient in the airflow rotation: since the grading area is the annular area between the outer edge of the turbine and the cylinder wall, the airflow only enters from a tangential air inlet, so the gas velocity is higher in the air inlet area, and the air flow is farther away from the air inlet. The speed is low, which forms an unstable flow field in the annular classification area, which affects the classification efficiency. the

3. No planar vortex can be formed: the turbine of the current turbine classifier is only a simple straight cage rotor without horizontal partitions, and the classifying blades are also made of flat steel, so that the formed rotating air flow is not a planar vortex, but a spiral Airflow, and the flow rate of gas sucked in the upper part of the cage is faster, while the speed of air sucked in the lower part of the cage is slower, thus affecting the classification efficiency.

4. The coarse ash cannot be cleaned effectively. The current turbine classifier is designed with secondary air entering tangentially in the lower part of the classifying cylinder to clean the coarse ash. If the wind speed of this secondary air is high, it is easy to The falling coarse ash is lifted up in large quantities, so as to prevent the material classification in the upper part of the anti-interference classification area. If the wind speed is low, the cleaning effect on the coarse ash cannot be achieved.

3.Calcium powder separator

4.Cement powder separator

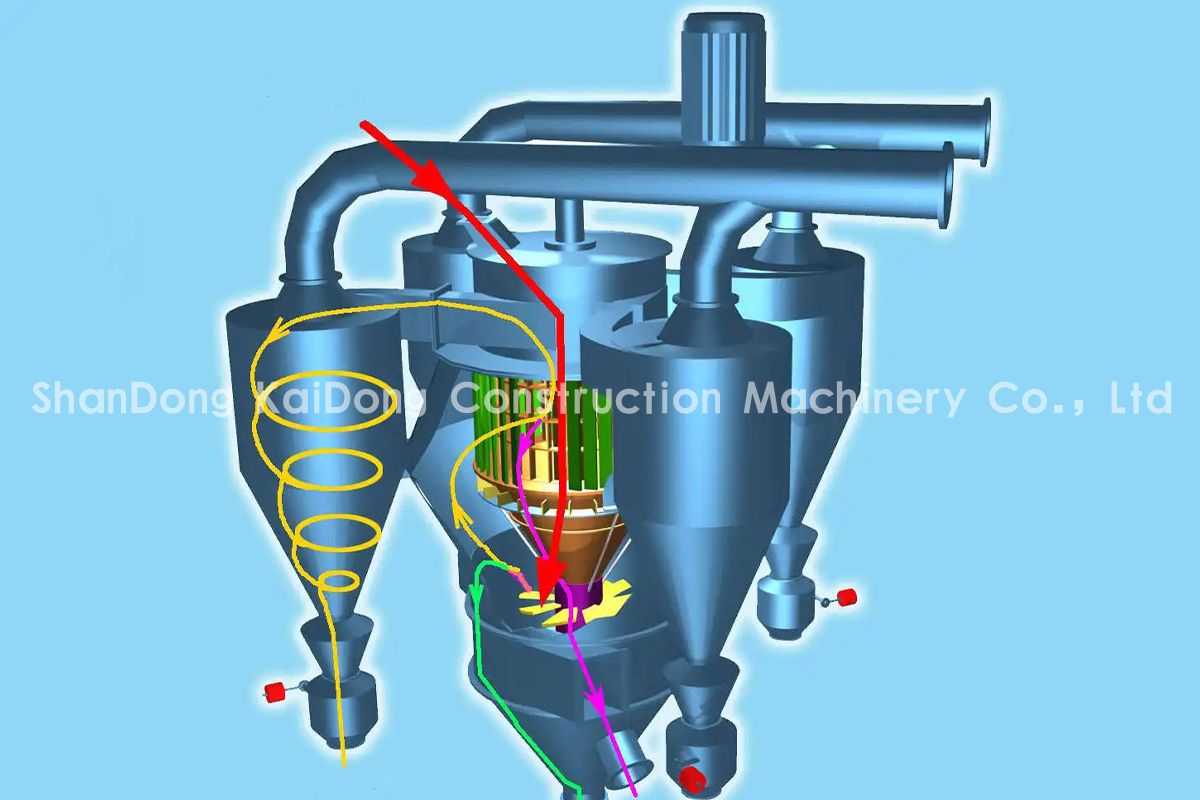

KD series ultra-fine powder classifier completely overcomes these shortcomings of turbo classifier, and its outstanding advantages are:

1. The designed straight cage rotor is a cage-shaped rotor composed of multi-layer horizontal baffles and vertical special-shaped grading blades. The horizontal baffles make the airflow in the grading area form a stable horizontal vortex, and the special-shaped grading blades make it enter the cage from the surface of the cage. The internal classification airflow maintains the same flow velocity at any point, and its relative velocity difference is less than 5%, so the flow field in the classification area is uniform and stable, so the classification accuracy is very high.

2. A number of guide vanes with "concave" grooves are evenly arranged in the middle part between the cage rotor and the outer casing, and the dust-containing gas must pass through several gaps of about 15mm between the guide vanes along the tangential direction. Entering the annular classification space composed of guide vanes and cage-shaped rotors, the side wall effect is completely eliminated due to the existence of guide vanes, the content of fine ash in coarse ash is greatly reduced, and the classification efficiency is greatly improved.

3. The coarse ash falling into the coarse ash hopper is washed by the lower updraft, and the fine ash in the coarse ash is brought into the classification area again for classification.

4. Due to the uniform and stable flow field and the high rotational speed of the airflow, the generated centrifugal force and centripetal suction of the airflow are both strong, so the classification accuracy is very high, and the material-air ratio can reach 2.0-2.5, which is higher than that of the turbo classifier. (0.7~1.0) is 2~3 times higher, and the air volume for classification is only half of that of the turbine classifier, so the energy consumption of the system is greatly reduced. The energy consumption of the classification system with a processing capacity of 60T/H is only 120KW, and the processing capacity is The energy consumption of the 40T/H grading system is only 100KW.

5.Powder separator

You Might Also Like