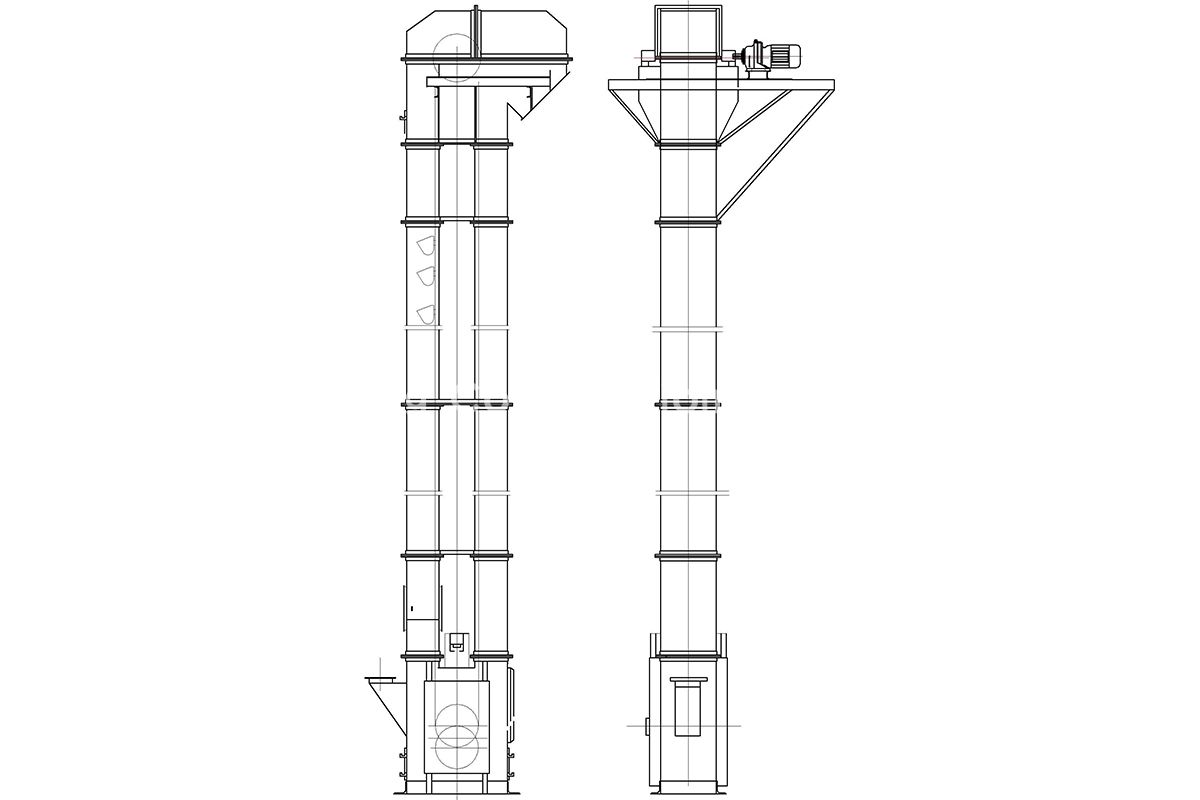

Bucket Elevator

Bucket Elevator

Range of application:Calcium carbonate crushing and processing, gypsum powder processing, power plant desulfurization, non-metallic mineral powder making, coal powder preparation, etc.

Applicable materials:Limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, pyroxene, quartzite, bentonite, etc.

Maximum lifting height:28-32.7m

processing capability:3-60m³/h

The elevator has the advantages of large conveying capacity, high lifting height, smooth and reliable operation, and long service life. Its main performance and parameters are in line with JB3926----85 Vertical Bucket Elevator (the standard is equivalent to the reference to international standards and foreign **standards), and the hauling circular chain is in line with MT36----80 High-strength Circular Chain for Mining Use. This elevator is suitable for conveying powdery, granular, and small-block non-abrasive and abrasive materials, such as coal, cement, stone, sand, clay, and ores, etc. As the hauling organization of elevator is the chain of circular rows, it is permissible to convey the materials of higher temperature.

Hoist performance characteristics

1, the bucket elevator drive power is small, the use of inflow feeding, induced discharge, large-capacity hopper intensive arrangement, in the material lifting almost no return and digging phenomenon, so less ineffective power.

2, bucket elevator lifting range, this type of elevator on the type of material, characteristics of the requirements of less, not only can lift the general powdery, small granular materials, but also can lift the abrasive materials, sealing is good, less environmental pollution.

3, good operational reliability, ** design principles and processing methods to ensure the reliability of the machine operation, trouble-free time of more than 20,000 hours, the elevator runs smoothly, can reach a high lifting height.

4, long service life of the bucket elevator, elevator feeding takes the inflow type, no need to dig the material with a bucket, the material is rarely squeezed and collision between the phenomenon. In the design to ensure that the material in the feeding, unloading less scattered, reducing mechanical wear.

Elevator working principle

The hopper scoops up the material from the storage below, lifts it to the top with the conveyor belt or chain, turns it downward around the top wheel, and the bucket elevator dumps the material into the receiving chute. Belt-driven bucket elevators have rubberized drive belts mounted on the lower or upper drive drums and on the upper and lower reversing drums. Chain-driven bucket elevators are generally equipped with two parallel drive chains, with a pair of drive sprockets on the top or bottom and a pair of redirecting sprockets on the bottom or top. Bucket elevators are generally equipped with a housing to prevent dust from flying inside the machine.

Elevator technical parameters

Model | Maximum lifting height | transport volume | Hopper distance | Motor power(kw) |

200 Model | 28 | 8-15 | 500 | 3-5.5 |

250 Model | 30 | 10-25 | 500 | 4-7.5 |

300 Model | 30 | 25-35 | 500 | 5.5-11 |

315 Model | 40 | 30-40 | 512 | 5.5-15 |

400 Model | 40 | 45-60 | 512 | 11-22 |

500 Model | 40 | 65-80 | 512 | 15-30 |

630 Model | 40 | 100-120 | 688 | 18.5-37 |

You Might Also Like